Pre-Plated Steel – They are also known as galvanized sheet metal components. They come with a protecting coating to stop them from rusting. In addition they guidance straightforward sheet metal processing strategies because of amplified ductility.

When bending a workpiece, it is going to By natural means spring again slightly after the load is lifted. Thus, it has to be compensated for when bending. The workpiece is bent past the required angle, so it will require the desired condition following springback.

To generally be certain, chopping metal sheets is achievable using shear, which employs shear forces to chop with the metal. There are 3 solutions involved in this sort of reducing – shearing, punching, and blanking.

Thinking about the resilience from the part for the duration of bending, the angle input for the push brake controller should be fewer than ninety degrees.

CATIA can be used for specialized Examination and preparing to simulate the feasibility on the bending peak for the element. The next needs to be taken into account when conducting the simulation:

The design of extra acceptable bending tooling will Engage in a vital job in growing the appliance on the bending forming procedure.

Labor: Most professional roofers demand about $11 for every square foot, or approximately $60 for each hour. Booking a roofing project in the summertime will boost installation prices due to the fact need is at its highest.

Holes and Slots Orientation: These components are also very important. Holes and slots diameter should not less than be as significant as being the thickness on the sheet metal. Also, holes really should be fairly spaced. They need to never be as well near the edge of the material.

This could potentially cause alignment and orientation problems, resulting in inaccurate elements and longer manufacturing moments. Due to this fact, it is critical to diligently consider the geometry and material thickness to make certain that the ultimate product or service satisfies the expected requirements and criteria.

The incredibly substantial amount of precision wanted throughout the aerospace marketplace would make CNC machining an appropriate production procedure for your sector.

The panels easily expand and deal less than switching temperatures, are light-weight and will be put in in excess of an current roof.

Metal roofs Price greater than a number of other roof styles, but their durability and longevity are worth it For most homeowners. Buying a metal roof may conserve you from purchasing roof repairs Sooner or later.

Aluminum – A different well known choice for the production sectors. It comes with a wonderful energy-to-body weight ratio. What's more, it includes numerous characteristics read more that assistance it meet up with several application prerequisites.

Metal is extremely reusable, as many metal roofs are created of thirty%–sixty% recycled metal. Their significant toughness also signifies they don’t ought to be replaced as usually.

Tia Carrere Then & Now!

Tia Carrere Then & Now! Tony Danza Then & Now!

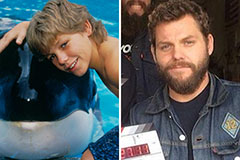

Tony Danza Then & Now! Jason J. Richter Then & Now!

Jason J. Richter Then & Now! Jonathan Lipnicki Then & Now!

Jonathan Lipnicki Then & Now! Suri Cruise Then & Now!

Suri Cruise Then & Now!